The closing and stitching of industrial sacks is not an accessory component, but a critical part of the packaging and packing process, especially when handling powdery and sensitive products.

The Sack Closure: A Critical Point in Flour Transport

Flour presents specific characteristics that directly affect the design of the closure system: flowability, dust generation, moisture sensitivity, and high handling during logistics. A poor closure can compromise the integrity of the packaging and packing, even when the sack meets structural requirements.

From an industrial perspective, packaging and packing solutions for flour transport must ensure:

- Effective product containment

- Mechanical resistance at the closure area

- Stability during stacking and handling

- Compatibility with automated closing systems

The closing system must be designed according to the real-world use of the sack and transportation conditions.

Common Problems Caused by Improper Closures

Failures in the closure system often become apparent along the logistics chain, not necessarily during filling. The most frequent issues include:

- Product leakage due to micro-openings in the stitching

- Moisture or contaminant ingress

- Paper weakening at the sack opening

- Tearing during transport or stacking

These issues directly impact the efficiency of packaging and packing, increasing product loss, incidents, and operational costs.

Closing Systems Used in Flour Sacks

Industrial Stitching

Stitching remains one of the most widely used methods for closing paper sacks in the flour industry. It’s a mechanical process that demands materials capable of withstanding repeated tension without degradation.

In industrial packaging and packing, stitching offers:

- High mechanical strength

- Reliability during medium and long-distance transport

- Adaptation to high-speed production lines

The quality of the paper used in the closure zone is crucial to prevent tearing and ensure stitching continuity.

Complementary Closures in Multi-Layer Structures

In specific applications, additional solutions may be incorporated such as heat sealing, internal reinforcements, or hot-melt systems to provide greater closure stability against humidity or fine dust—especially in certain packaging and packing formats.

In all cases, packaging and packing must be designed consistently with the chosen closing system and the existing production process.

Importance of Technical Paper in the Closure Area

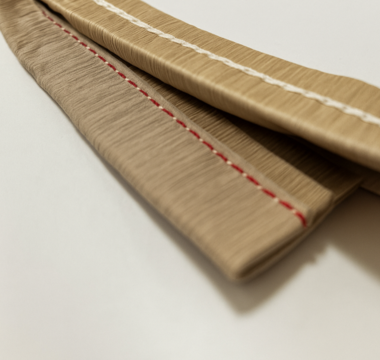

The performance of the closure is directly linked to the paper used. Variables such as basis weight, tear resistance, and flexibility influence stitching reliability and closure durability, particularly when using technical papers designed for stitching applications, like crepe paper for sack stitching.

A technical approach to packaging and packing for flour considers:

- Structural reinforcement at the sack mouth

- Paper behavior during continuous stitching

- Material stability during transport

Choosing the right paper is key to avoiding recurring closure failures.

Integration in Automated Industrial Processes

In the flour industry, closing systems must operate reliably within automated production lines without causing stoppages or incidents.

Properly designed packaging and packing allows:

- Consistent production speeds

- Fewer stitching errors

- Uniform results in high-volume batches

Compatibility between paper, closing system, and machinery is a decisive factor.

Food Safety and Product Control

The sack closure plays a vital role in food safety. It must prevent unnecessary exposure of the product and ensure protection throughout the logistics cycle.

Materials used in packaging and packing for flour must be food-grade and maintain their mechanical properties up to the final destination.

Sustainability in Sack Closures

Sustainability is an increasingly important factor in industrial packaging and packing. For flour sacks, closing solutions must be compatible with paper-based structures and efficient recycling processes.

Using appropriate technical papers maintains closure strength without the need for unnecessary materials.

Real-World Applications in the Flour Sector

Closing solutions are adapted to various uses within the agri-food sector, sharing technical needs with other powder and bulk products, as is the case with feed and cereal sacks.

- Transport of flour for industrial bakeries

- Specialized food applications

- Large-format sack logistics

In all cases, packaging and packing must respond to real handling and transport conditions, not just theoretical specifications.

Arrosi’s Technical Solutions for Industrial Sack Closing and Stitching

Sack closing and stitching is an industrial application that requires specific materials and a rigorous technical approach. In this field, packaging and packing efficiency directly depends on the quality of the paper used in the closure area.

At Arrosi, we develop technical papers for sack closing and stitching applications, designed to ensure strength, stability, and reliability in demanding industrial processes such as flour transport.

For those interested in staying updated on innovations, applications, and developments in this area, Arrosi shares technical and corporate content through its LinkedIn profile, complementing its industrial activity in packaging and packing.

To learn more about these applications, you can visit our dedicated section on industrial sack closing and stitching, where we detail solutions tailored to sectors like food and, in particular, the safe transport of flour.

Frequently Asked Questions About Sack Closing and Stitching for Flour

Why is sack closure important in flour transport?

Because it prevents leaks, moisture ingress, and contamination during handling and transport. In industrial packaging and packing, closure is the most sensitive point and determines the safety of the product throughout the logistics chain.

Is stitched closure compatible with automated processes?

Yes, as long as the paper and stitching system are properly designed. Technical papers enable stable operation on high-speed lines, reducing incidents and downtime.

How does closure contribute to food safety?

It prevents the product from being exposed to external agents during transport and storage. In food-grade packaging and packing, it guarantees product protection and compliance with hygiene and safety standards.

What solutions does Arrosi offer for sack closing and stitching?

Arrosi develops technical papers for sack closing and stitching, engineered for demanding industrial processes and designed to ensure strength, consistency, and reliability in packaging and packing for flour transport.