Importance of sealing of bags in the agri-food industry

When packaging bulk products like cereals, flour, or feed, a strong, clean, and reliable closure is essential. The sealing of bags provides an effective barrier against moisture, contamination, and spillage. Two common techniques stand out in this field: sewing with crepe paper tape and closing with heat sealing.

Both methods ensure integrity of contents and safe handling throughout the supply chain. Additionally, they enable high-speed processing in automated packaging lines, contributing to efficiency and productivity.

Arrosi´s systems for sealing of bags

At Arrosi, we design and manufacture complete solutions for the sealing of bags. Our systems are compatible with a wide range of machines and adapted to various packaging materials such as kraft paper, polyethylene, or laminated films.

1. Sewing of bags using crepe paper tape

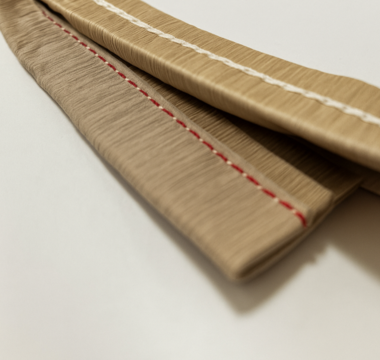

This method involves attaching a crepe paper tape to the top of the bag and stitching it using industrial sewing machines. The tape reinforces the seam, prevents leakage, and increases mechanical resistance.

Arrosi supplies crepe paper tape in different finishes—white (bleached), brown (unbleached), and custom colors—with adjustable grammage, stretch level, width, and inner/outer diameter, tailored to each client´s needs.

Our crepe paper tape is compatible with major sewing machines on the market, including Fischbein, Newlong, Union Special, Thar, Yao Han, and Siruba, allowing for smooth integration into both automatic and semi-automatic lines.

This technique is widely used not only for food and feed but also for chemical and phytosanitary products that require strong, flexible, and safe closures. Learn more in our article “Use of crepe paper tape in sealing bags for agrochemical products.”

2. Closing of bags by heat sealing

For applications that require seamless sealing of bags, Arrosi offers tapes made from polyethylene and/or hot-melt tape. This system creates a continuous thermal seal at the top of the bag, blocking out moisture and dust—ideal for laminated or multilayer materials.

For high-speed packaging environments, heat sealing ensures excellent efficiency and tight, professional results. We recommend reading the article “Heat sealing in bag closure: performance and precision for industry” to explore its full potential.

Both sewing and heat sealing methods can be selected based on the product´s nature and packaging material, offering a balance of reliability, sustainability, and cost-efficiency.

Technical features of crepe paper tape

The crepe paper tape used by Arrosi is known for its high flexibility, controlled elongation, and tear resistance. These qualities help absorb mechanical stresses during filling, transport, and palletizing.

Its corrugated structure acts as a shock absorber, protecting the bag seam from tearing. Being cellulose-based, it is also recyclable—contributing to sustainable industrial waste management.

Applications of sealing of bags

Arrosi’s sealing of bags systems with crepe paper or heat sealing solutions are used in a wide variety of industries:

- Agri-food: animal feed, cereals, fertilizers, additives

- Food: flour, cereals for human consumption, powdered milk

- Chemical industry: charcoal, phytosanitary products, foam agents

These solutions help maintain product quality, reduce contamination risks, and ensure safety during storage and distribution.

Key factors for effective sealing of bags

The performance of sealing of bags depends on a precise combination of material quality, machine calibration, and environmental factors:

- Thread tension and uniformity in sewing to prevent seam openings or tearing

- Tape compatibility with bag type, thickness, and material

- Environmental conditions like humidity and temperature can affect adhesion or stitching behavior.

By using high-quality tapes and properly adjusted machinery, manufacturers can achieve reliable, hygienic, and visually consistent closures.

Arrosi’s commitment to sealing performance

As a specialized manufacturer, Arrosi offers custom solutions to meet the unique requirements of each client. We provide flexibility in defining tape width, inner and outer diameter, and technical parameters like grammage and elasticity.

Our partnerships with sewing and sealing machine manufacturers ensure full compatibility with the most widely used equipment in the industry. Thanks to our continuous innovation and sustainability-driven approach, Arrosi is a trusted reference in the sealing of bags for feed, cereals, and industrial packaging.