Crepe Paper: Technical Functionality in Phytosanitary Product Packaging

Adaptation to Demanding Production Lines

Phytosanitary products packaging must meet very strict technical requirements: sealing integrity, stacking resistance, traceability, and regulatory compliance. Crepe paper reinforces the sack´s stitched area by offering:

- Protection of the seam against thread wear caused by friction.

- Tear resistance, even under high mechanical stress.

- Cleaner and more uniform sealing, optimizing both functionality and the final appearance of the package.

Compatibility with Automatic Stitching

Designed for high-speed stitching lines, crepe paper maintains consistent elongation that prevents jamming and tearing. This reduces machine downtime and improves efficiency in industrial packaging processes for phytosanitary products.

Arrosi Solutions for Industrial Sack Stitching and Sealing

At Arrosi, we’ve developed specific applications tailored to real market needs. We manufacture our products with a technical, practical, and sustainable approach.

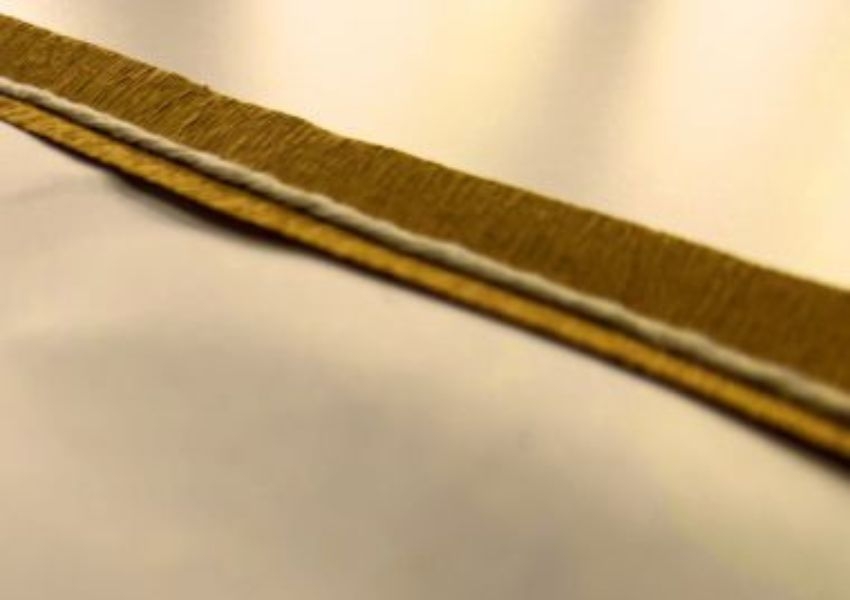

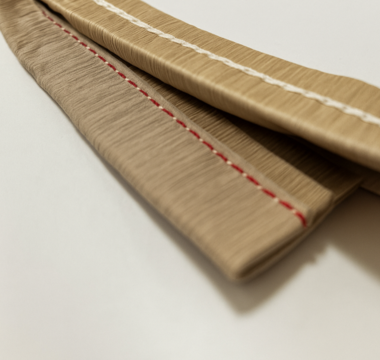

Stitching with Crepe Paper Trim

We offer crepe paper trims in white, natural (brown), and custom colors, compatible with the main sack stitching machines, such as:

- Fischbein

- Newlong

- Union Special

- Thar

- Yao Han

- Siruba

This type of stitching provides maximum resistance, prevents the entry of foreign objects into the sack, and enhances content protection during transportation and storage. It is an optimal solution to ensure the integrity of phytosanitary product packaging under demanding logistics conditions.

Operational Benefits of Crepe Paper

Reinforcement and Durability

Made from virgin cellulose, crepe paper offers an excellent balance between strength and flexibility. It withstands load stress, vibrations during transport, and extended storage without compromising the integrity of the seal.

Packaging Safety and Traceability

Phytosanitary products packaging requires clear identification of batch, production date, and other critical data. Crepe paper does not interfere with these print zones and ensures a seal that does not compromise printed information on the sack.

Industrial Sustainability

Crepe paper helps reduce the use of plastic reinforcements or non-recyclable materials in the sack´s sealing area. This allows for the design of mono-material packaging that is easier to recycle and aligned with circular economy and sustainability strategies.

- Grammage: from 85 to 130 g/m², with high mechanical resistance and controlled elongation.

- Colors: white, brown, and other custom shades.

- Presentation: rolls with widths and lengths adapted to automatic or manual stitching lines.

Arrosi provides customized crepe paper solutions to suit various types of phytosanitary products packaging, depending on volume, product density, and logistics requirements.

Practical Application in Stitching Lines

Integration Procedure

In closing lines, crepe paper is inserted as a band between the thread and the sack body, acting as a cushion. This allows for:

- Reduced thread wear

- Prevention of tears from mechanical tension

- Uniform and clean sealing

This reinforcement enhances the sack’s performance and extends its useful life, even under intensive use conditions.

If you´re interested in how packaging influences logistics performance, we recommend reading our article on optimizing storage for packaged products.

Crepe Paper and Sustainability in Phytosanitary Products Packaging

Reduction of Non-Recyclable Materials

Replacing plastic tapes with crepe paper enables the design of phytosanitary products packaging that is more environmentally friendly. This facilitates sack separation and recycling at the end of its lifecycle.

Recyclability and Compostability

Crepe paper is easily recycled through conventional paper streams or can be composted under industrial conditions, especially when used in mono-material sacks. This advantage is key for companies seeking environmental certifications or aiming to improve their ESG (Environmental, Social, and Corporate Governance) indicators.

Discover more sustainable applications in our article on the use of crepe paper in the storage of sensitive products.

More Than a Reinforcement—A Comprehensive Solution

Crepe paper is a technical solution that enhances the performance, safety, and sustainability of phytosanitary products packaging. Its implementation enables:

- A strong and uniform seal

- Protection of the seam and thread

- Compatibility with automated production lines

- Reduced environmental impact of the packaging

With proper design, this material not only optimizes the stitching process but also strengthens the company’s commitment to quality, efficiency, and sustainability.

Need a custom solution for your stitching lines?

Contact Arrosi’s technical team and discover how to integrate crepe paper into your processes with maximum efficiency and reliability.