What Is Paper with Hot Melt?

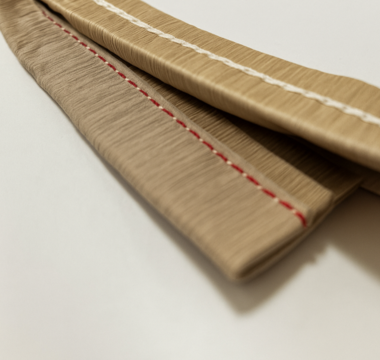

At Arrosi, hot melt refers to a layer of thermoplastic adhesive applied to paper, activated by heat to seal bags through heat sealing. We produce plain paper from 60 g/m² to 200 g/m², with a hot melt coating ranging from 10 g/m² to 30 g/m². This coating provides a durable and airtight seal, ideal for industrial heat sealing machines without the need for stitching or binding.

Advantages of Hot Melt Sealing

Airtightness and Protection

Sealing with hot melt creates a continuous barrier that prevents the entry of dust, moisture, or other contaminants. It’s the ideal solution for sensitive products such as flour, feed, fertilizers, or chemicals.

Industrial Compatibility

Hot melt paper is compatible with common heat sealing machinery, and at Arrosi, we adapt it to the technical specifications of each client—from roll width and diameter to the amount of adhesive applied.

Flexible Grammage and Thickness

Available formats from 60 to 200 g/m² allow for a balance between structural lightness and mechanical strength, while coatings of up to 30 g/m² ensure reliable sealing even under demanding conditions.

Production Time Efficiency

By replacing stitching or binding with heat sealing, the process is automated, handling time is reduced, and operational costs are minimized—resulting in higher productivity and fewer errors.

Production and Quality Processes

Coating Control

The hot melt layer is applied using precision coating systems, ensuring an even distribution of the adhesive, which translates into uniform, fault-free seals.

Traceability and Customization

Thanks to our integrated manufacturing, we can provide solutions tailored to each production line: rolls with different diameters, specific widths, and mechanical properties adapted to each client’s heat sealing speed and temperature.

Regulations and Safety

Our hot melt paper complies with applicable regulations across sectors, including those concerning food contact, operator safety, and thermal resistance of packaging.

Key Sectors for Hot Melt Sealing

Animal Feed and Pet Food

Airtight sealing with hot melt preserves product quality, prevents moisture, and protects against external contaminants, helping maintain nutritional value and food safety.

Flour, Cereals, and Powdered Milk

In sectors where hygiene is a priority, closure without mechanical stitching or staples eliminates contamination risks and enhances compliance with food safety standards.

Fertilizers and Chemicals

Bags sealed with hot melt prevent leaks and protect both the product and the environment, facilitating the safe transport and storage of granular or powdered compounds.

Binding or Hot Melt: Which System Is More Effective?

Unlike polyethylene binding or traditional stitching—which involve slower processes, greater mechanical complexity, and less airtight sealing—the hot melt heat sealing system stands out for its speed, lower maintenance, and higher efficiency. While binding may allow leaks or deteriorate with handling, hot melt creates a continuous, high-resistance seal. Additionally, it reduces the need for extra materials and simplifies production lines, boosting output per minute without compromising seal safety.

How to Implement Hot Melt in Your Plant

- Assess current machinery: Ensure your heat sealers can work with hot melt coated paper

- Specify the right paper: Choose grammage, width, and adhesive layer based on your product and packaging line.

- Request samples: Arrosi provides industrial samples for real production testing.

- Train operators: Temperature, pressure, and speed adjustments must be managed to guarantee uniform sealing.

- Monitor and ensure quality: Set in-line quality controls to detect any sealing defects and optimize technical parameters.

Hot Melt at Arrosi

Hot melt paper represents a tangible improvement in bag sealing processes: cleaner, faster, and more reliable. Compared to conventional solutions like stitching or binding, heat sealing offers efficiency, hygiene, and adaptability. At Arrosi, we specialize in designing and manufacturing customized hot melt solutions, integrating the technical requirements of each sector and machinery. If you´re looking to optimize your packaging line, this technology can make a real difference.