Challenges in Packaging Cutting Tools

Blades and saws are high-value yet delicate components. Although durable, their edges can deteriorate during transport or storage if not properly protected. The main challenges include:

- Preventing damage to sharp edges: Minor impacts can significantly reduce their lifespan.

- Moisture protection: Exposure can cause oxidation in metal components.

- Space optimization: In industrial packaging, every centimeter matters.

- Sustainability: The industry demands recyclable materials with low environmental impact.

To address these challenges, crepe paper stands out as a technical and sustainable protective packaging material.

Crepe Paper: A Technical and Versatile Protective Packaging Material

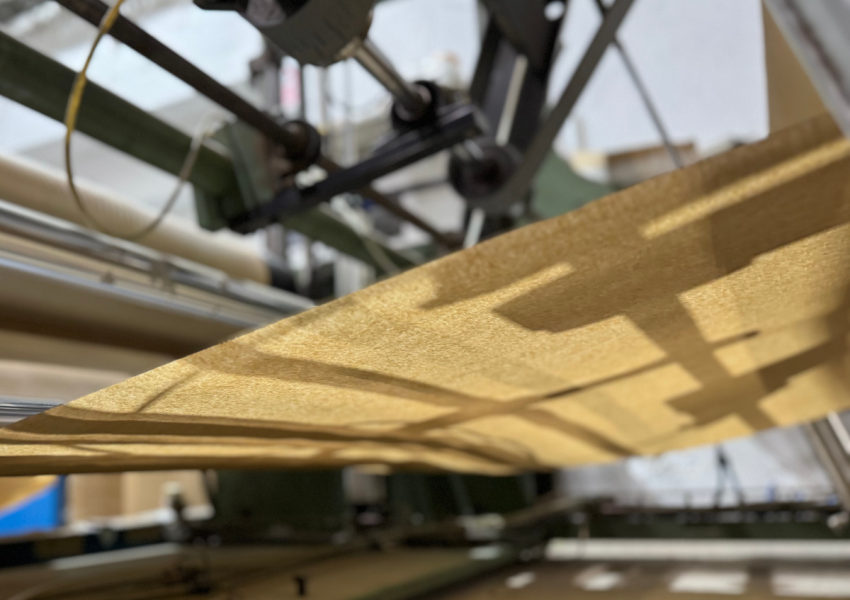

Crepe paper is not just a cellulose-based substrate—it is a purpose-designed protective packaging material offering flexibility, shock absorption, and mechanical resistance. Its textured and elastic structure allows it to conform to the contours of blades and saws, creating a protective layer that prevents internal movement and friction.

Key Features for Cutting Tool Applications:

- Controlled elasticity: The creped structure allows flexibility without losing firmness.

- Mechanical strength: Withstands stresses from transport and handling.

- Impact and vibration absorption: Protecting sensitive edges and tips.

- Regulated permeability: Adjustable to meet specific packaging needs.

Competitive Advantages Over Other Materials

Compared to plastics or synthetic foams, crepe paper offers a superior balance between technical performance and sustainability. Its main advantages include:

- Renewable origin: Made from plant-based cellulose fibers.

- Biodegradability and recyclability: Simplifies end-of-life material management.

- Industrial compatibility: Easily cut, folded, printed, and converted into various formats.

- Eco-friendly image: Meets modern client demands and sustainability standards.

These attributes make crepe paper the ideal protective packaging material for sectors prioritizing both safety and environmental responsibility.

This unique value is further strengthened in a context where paper is increasingly recognized as the future of industrial packaging. To dive deeper into this topic, we recommend our article: Why Paper is the Future of Industrial Packaging: Sustainable Keys and Real-World Applications.

Moreover, the development of new uses shows how crepe paper continues evolving to meet industrial needs. Discover practical examples in our article on Innovations in Crepe Paper for the Industrial Sector.

Practical Applications in Blade and Saw Packaging

Crepe paper is efficiently used across different stages of packaging for cutting tools:

1. Individual Blade Protection

Supplied in rolls or pre-cut sheets to wrap each item, preventing direct contact between sharp edges.

2. Separation Between Saws or Discs

Used as an interleaving layer to avoid friction and abrasion during transport.

3. Filling and Securing Inside Boxes

Its elasticity allows it to act as a securing material inside packaging, minimizing item movement.

4. Sustainable Presentation and Finish

Creates a more aesthetic packaging aligned with brand image, compared to less appealing plastic materials in premium markets.

Sustainability and Added Value in the Logistics Chain

Using crepe paper as a protective packaging material not only ensures the safety of blades and saws—it also strengthens companies’ sustainability strategies. Being recyclable and biodegradable, it helps reduce the carbon footprint and supports the transition toward more responsible supply chains.

In addition, its adaptability in terms of grammage and color offers manufacturers the ability to customize their solutions, combining protection and brand identity in one material.

A Technical Material for the Future of Tool Packaging

Protecting blades and saws requires technical solutions that combine safety, durability, and environmental responsibility. In this context, crepe paper proves to be the most efficient protective packaging material, delivering high performance along with clear sustainable value.

Its use in the cutting tools sector not only prevents damage and streamlines logistics but also strengthens the brand image of companies committed to responsible alternatives.

Looking for a protective packaging material tailored to your needs?

At Arrosi, we develop crepe paper solutions designed to ensure the safety of your cutting tools while optimizing your logistics chain with a sustainable approach. Contact us to discover our crepe paper applications.