Innovations in the Strength of Crepe Paper

One of the most significant advances in industrial crepe paper is its strength. Crepe paper may seem like a fragile material at first glance, but when treated properly, it can withstand heavy loads and resist adverse conditions. In the packaging sector, for example, crepe paper is increasingly used to wrap and protect delicate products, offering a sustainable and effective alternative to plastics.

At Arrosi, we have worked on creating crepe paper with high tensile strength. This type of paper is especially useful in sewing sacks for agricultural and mineral products, where packaging must withstand heavy weights without tearing.

Sustainable Solutions with Crepe Paper

Another area where crepe paper is setting a trend is sustainability. As industries seek eco-friendly alternatives to plastics and other petroleum-derived products, crepe paper has emerged as an ideal solution. Being biodegradable and recyclable, this material aligns with current environmental demands, offering companies the possibility to reduce their carbon footprint.

In the packaging sector, for instance, many companies are opting to use crepe paper instead of bubble wrap or polyethylene foams to protect their products during transportation. Crepe paper, being more flexible and impact-resistant, provides excellent cushioning without harming the environment.

Crepe Paper in Bookbinding

One of the areas where Arrosi has made a notable impact is in bookbinding. Thanks to its elasticity, crepe paper has become a crucial material in this process. Its ability to adapt to different shapes and volumes makes it the perfect choice for securely binding books. Moreover, its resistance to wear ensures that books maintain their structural integrity over long periods, even under constant use.

We have worked with publishers and printing companies to develop crepe paper solutions that not only ensure the quality of the binding but also meet the aesthetic and functional requirements demanded by the publishing market.

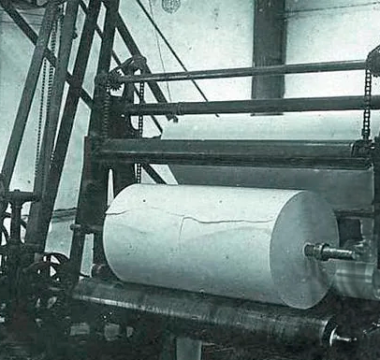

Technological Innovations in Crepe Paper Production

Technology has played a crucial role in the evolution of industrial crepe paper. Nowadays, the manufacturing process has advanced significantly thanks to automation and improved quality controls. At Arrosi, we have invested in state-of-the-art machinery that allows us to produce crepe paper with unmatched precision in terms of thickness, elasticity, and strength.

Additionally, we have developed more sustainable production methods, optimizing water usage and reducing carbon emissions in our factories. These innovations not only allow us to offer high-quality products but also ensure that we are contributing to a greener future.

Applications in the Electrical Industry

Crepe paper has proven its usefulness not only in sectors like packaging and bookbinding but also in the electrical industry. In this field, crepe paper is used as insulation and protective material in the manufacturing of transformers and electrical cables. Its ability to withstand high temperatures and resist moisture makes it an essential component in the production of these devices, ensuring safe and long-lasting performance.

At Arrosi, we understand the importance of providing high-quality solutions for specialized industrial applications, such as insulation in the electrical industry. Our industrial crepe paper is designed to meet the most demanding standards, providing effective and durable insulation in high-voltage transformers and cables.

Crepe Paper as a Versatile Material

One of the most outstanding features of crepe paper is its versatility. In the industrial sector, its applications are so varied that they range from packaging to surface protection and the manufacture of industrial filters. This material can adapt to different shapes, textures, and thicknesses, making it a preferred choice for many industries looking for specific solutions to their needs.

At Arrosi, we pride ourselves on working with our clients to develop crepe paper products that meet specific requirements. Whether in agriculture, where a material that can withstand extreme weather conditions is needed, or in logistics, where flexibility and durability are required for the safe transportation of goods, our crepe paper has proven to be an effective and reliable solution.

The Future of Crepe Paper in the Industrial Sector

Crepe paper continues to evolve, and the possibilities for its use in the industrial sector are virtually endless. With the rise of the circular economy and the growing demand for sustainable materials, crepe paper is positioning itself as one of the most promising solutions for industries seeking to reduce their environmental impact without compromising functionality and efficiency.

At Arrosi, we are committed to continuous innovation in the production of industrial crepe paper. Our research and development team constantly works to improve the material´s properties, seeking new ways to adapt crepe paper to the changing challenges of the market.

Conclusion

Crepe paper has proven to be much more than a decorative material. In the industrial sector, its versatility, strength, and sustainability have made it a preferred choice for many companies. At Arrosi, we continue to bet on innovation, developing custom solutions that allow our clients to fully take advantage of the benefits of crepe paper in their production processes.