Raw Materials

Crepe paper is mainly made from wood pulp, which can come from various types of trees, such as spruce, pine, or eucalyptus. This pulp undergoes a refining process to turn it into a pulp that will serve as a base for the paper. During this process, colour can be added to the pulp to obtain a uniform and permanent colour, as the cellulose fibres are completely dyed. After dyeing, the pulp may receive different additives depending on its intended use. This may include treatments to make it water resistant or flame retardants for decorative applications.

Formation of the Paper Sheet

Once the pulp paste has been thoroughly prepared, the fascinating and meticulous process of crepe paper production begins with the formation of the paper sheet. This fundamental and essential stage involves carefully pouring the pulp onto a finely woven and delicate mesh, which acts as an expert and sophisticated sieve, allowing the water to drain away in a controlled and precise manner, while the pulp fibres are meticulously retained and precisely moulded to create a sheet of paper of exceptional uniformity and unrivalled quality.

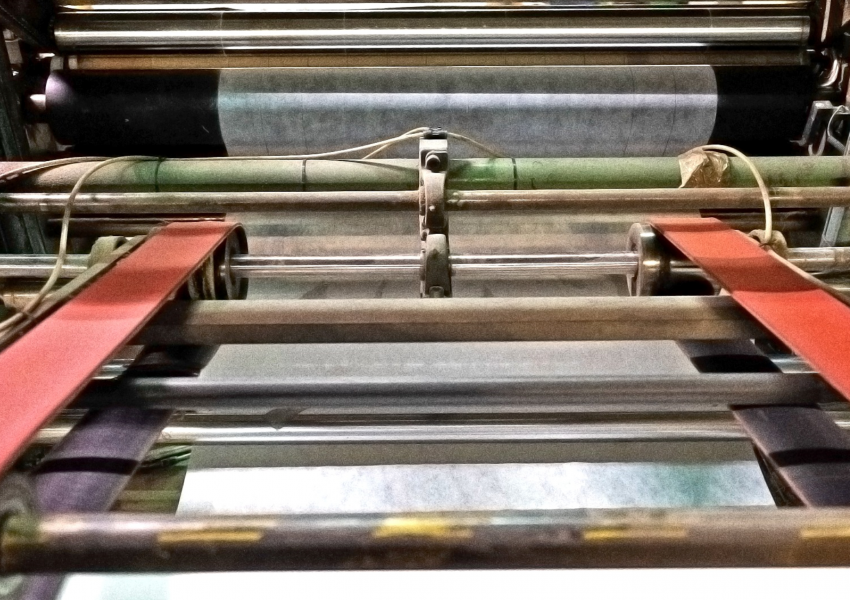

Drying

After forming, the sheet of paper is passed through press rolls to remove excess water and give it greater cohesion. It is then transported through a series of heated cylinders that completely evaporate the remaining moisture, leaving a dry sheet ready for the next step.

Creping

This is where the paper acquires its most distinctive characteristic: creasing. The creping process involves passing the sheet of paper through a steam-heated drying cylinder (Yankee) where a metal blade, known as a doctor blade, scrapes the paper. The interaction between the sheet of paper and the blade causes the paper to crumple and acquire the characteristic texture of crepe paper, creating those wrinkles that give it its unique texture and ability to stretch and conform to different shapes.

Packaging and Distribution

Once the crepe paper has been manufactured, it is packaged in rolls or sheets, ready for distribution to retail shops, wholesalers, or directly to consumers. This packaging and distribution process ensures that the paper gets into the hands of those who need it safely and efficiently.

Conclusion

Crepe paper is a staple in many areas of our lives, from decoration to packaging. Understanding the manufacturing process behind this material can help us appreciate it even more and use it more creatively. From its humble beginnings as wood pulp to its transformation into beautifully crumpled sheets of paper, crepe paper remains an impressive example of materials engineering.

So the next time you unroll a sheet of crepe paper to decorate a gift or create a craft, take a moment to remember all the effort and skill it takes to make this seemingly simple but surprisingly versatile product.

If you have any questions, would like to place an order, or simply want to know more about our products, please don´t hesitate to contact us. Our team is here to help you find the perfect solution for your projects.