What is crepe paper?

Crepe paper is a type of paper that has a wrinkled surface that gives it qualities such as elasticity, softness and malleability. This is the opposite of how the paper industry typically describes "kraft, parchment or smooth paper", which refers to a flatter, softer paper. The fibre or pulp used as the base ingredients to make crepe or kraft paper can be exactly the same. The variation occurs in the papermaking process, either by calendering the kraft (pressing it between two heated rolls) to smooth it or by creping (scraping) it from a roll (using a blade to gather the paper into a crumpled surface).

How did crepe paper get its name?

Crepe cloth, invented in the early 19th century, was a fabric that had a crinkled or pleated texture through the use of embossing techniques. Naturally, crepe paper has a similar look and feel and took its name from crepe cloth. The word "crepe" typically refers to things that are "crinkled". Even in the beauty industry, you will see wrinkle-reducing serums referred to as "crepe removers" or other similar terms.

Making Crepe Paper

To understand this material properly, it may be interesting to understand the process of its creation.

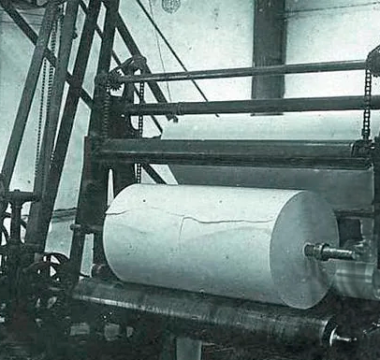

The manufacture of crepe paper is a peculiar process, to say the least, that integrates technical skills, scientific knowledge and a touch of ingenuity. It begins with the preparation of the pulp, which can come from sources such as virgin wood or recycled paper. This pulp is mixed with water and specific additives to form a liquid suspension, which acts as the essential base for papermaking.

Once the pulp is prepared, the sheet formation stage begins. The liquid suspension of pulp is poured onto a wire screen, where the water begins to drain away, leaving a thin layer of interwoven fibres.

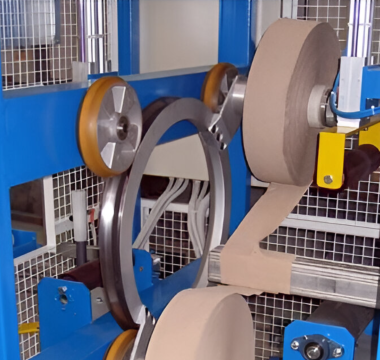

After the sheet of paper is formed in the above process, it is fed through a large cylinder called a "creping cylinder". This cylinder is specifically designed to alter the flat structure of the paper. It may be coated with special materials to improve the grip on the paper. Right at the point where the paper makes contact with the cylinder, a creping blade (also known as a doctor blade) is placed. This blade is essential to the process and must be perfectly adjusted to interact with the paper. Its function is to scrape or "pinch" the paper from the surface of the cylinder, which introduces creases and wrinkles into the sheet.

The position and angle of the creping blade are adjustable and are set according to the desired type of creping. A sharper angle and higher pressure can increase the intensity of creping, resulting in a paper with more elasticity and a more pronounced texture.

In some cases, adhesives or release agents are applied to the cylinder or to the paper sheet itself prior to creping. These compounds help control the adhesion of the paper to the cylinder and facilitate the creping process by allowing the blade to lift the paper more effectively.

The creping process must be carefully controlled to ensure paper consistency and quality. Paper moisture, machine speed, temperature and applied pressure are key factors that influence how the paper will be creped.

The result of a good creping process is a paper with even folds and a texture that allows it to stretch without tearing, ideal for applications that require some flexibility and strength.

Crepe paper is a star product

Crepe paper is a star product in various sectors due to its versatility and benefits.

Economic and Practical Benefits of Crepe Paper

Crepe paper is distinguished not only by its functionality but also by its cost-effectiveness, making it a preferred choice for companies looking to optimise their production and operating costs. Thanks to its low manufacturing cost, crepe paper offers an economical alternative to other more expensive materials without compromising on quality or functionality.

This material is adaptable to a variety of industrial and creative uses, making it extremely practical for customers in a wide range of sectors. From packaging and product protection to decoration and design, its versatility allows companies to use one material for multiple purposes, simplifying the supply chain and reducing the need to invest in multiple material solutions.

Green Benefits of Crepe Paper

Crepe paper not only offers economic benefits, but is also consistent with the ecological practices of contemporary companies. Produced using renewable resources such as forest products from sustainably managed sources and recycled paper, this material contributes to the sustainable management of natural resources.

It is a natural and fully recyclable material, which takes up little space and is available in all colours. And that´s because its production process is designed to minimise waste and reduce water and energy consumption, reinforcing the industry´s commitment to sustainable practices.

By choosing crepe paper, companies are not only opting for an effective and versatile solution; they are also actively contributing to their sustainability goals, enhancing their brand image and encouraging greater loyalty from environmentally conscious consumers.

Crepe Paper Applications

The versatility of crepe paper is extensive.

After all, once made, crepe paper becomes an extremely valuable resource with a wide range of practical applications. We can list and classify them in a number of ways, but to give you an idea, here are some of the ways in which it is used:

B2B applications of Crepe Paper

Closing and sewing of sacks:

Crepe paper is used in the closing and stitching of sacks in industries such as agriculture or food. Its strength and ability to keep products safe during transportation make it ideal for this purpose.

Food industry:

In the food industry, crepe paper is used to wrap and protect food, as well as to decorate products such as cakes and sweets. Its food safe nature and ability to retain freshness are key features.

Bookbinding:

Crepe paper is used in bookbinding to strengthen covers and provide an additional layer of protection. It can also be used to add colour and texture to the inside pages of books.

Surfboard manufacture:

Crepe paper is used as a mould in the manufacture of foam for surfboards, adapting to the complex shapes of the moulds. Its flexibility, porosity and texture prevent the material from sticking to the mould, facilitating a clean finish. This process is essential for creating the light and strong core of the boards, improving their buoyancy and manoeuvrability.

Wet wipes:

Crepe paper is an important component in the manufacture of wet wipes due to its ability to absorb liquids and its softness. It provides an effective and convenient wiping experience for a variety of uses.

Electrical insulation:

In electrical insulation applications, crepe paper is used as a barrier between electrical components to prevent short circuits and ensure safety. Its dielectric strength and ability to withstand high temperatures are crucial features.

Poultry and pig starting and transport:

Crepe paper is used in the grubbing and transport of chickens and pigs to provide a comfortable and safe environment during the process. Its ability to retain heat and absorb moisture is beneficial to animal welfare.

Pallet wrapping:

Crepe paper can be used as a perfect ecological substitute for stretch plastic film. It helps protect products from scratches, dirt and damage during transport and storage.

B2C Applications of Crepe Paper

Crafts and School Projects

In education, crepe paper is an invaluable resource for school projects and craft activities. Children enjoy exploring their creativity by using crepe paper to make flowers, masks, animals and a variety of other creations. Its soft, pliable texture makes it an easy material for little hands to manipulate, while its colourful appearance adds fun and excitement to any project.

Gift Wrapping

Crepe paper is also commonly used to wrap gifts in a creative and unique way. Its crinkled texture and bright colours make gifts wrapped with crepe paper stand out and become a gift in themselves. Plus, crepe paper is cheap and easy to find, making it a convenient choice for wrapping gifts of all kinds.

Art and Design

In the artistic realm, crepe paper is used in a variety of techniques and media. From collages and sculptures to paintings and drawings, crepe paper can add texture, colour and dimension to any work of art. Its versatility makes it a valuable material for artists of all ages and skill levels looking to add a unique touch to their creations.

Event Decoration

Crepe paper is a staple of event and party decorations. It is used to create garlands, pom poms, bows and other festive decorations that add a splash of colour and cheer to any celebration. Its wide range of colours allows for endless customisation, making it a popular choice for everything from birthdays to weddings.

Customisation and Tailor Made Solutions

Arrosi offers customisation and consultancy services to adapt crepe paper to the specific needs of each sector, whether industrial or non-industrial. After several generations of close collaboration with our customers, we are able to say that we effectively develop solutions that not only meet their operational requirements, but also promote efficiency and innovation.

Crepe paper: present and future

Crepe paper transcends its traditional function in handicrafts, becoming a valuable tool in the world of creativity and design. Its meticulous manufacturing process and its multiple applications make it a versatile resource. Whether used in industry, decorating events or creating unique works of art, crepe paper provides endless opportunities to express the imagination and add vibrant splashes of colour to our lives.

Although crepe paper is well known as a craft material, it is more than just a craft material; it is a crucial tool in the industrial world, facilitating creativity and functionality in multiple applications.

Contact us

If you are interested in purchasing crepe paper, please visit our contact page or request a case study to see in detail how our innovation in crepe paper manufacturing can be the solution your company needs.

We invite interested companies to contact us to explore how Arrosi crepe paper can enhance their production processes and end products.