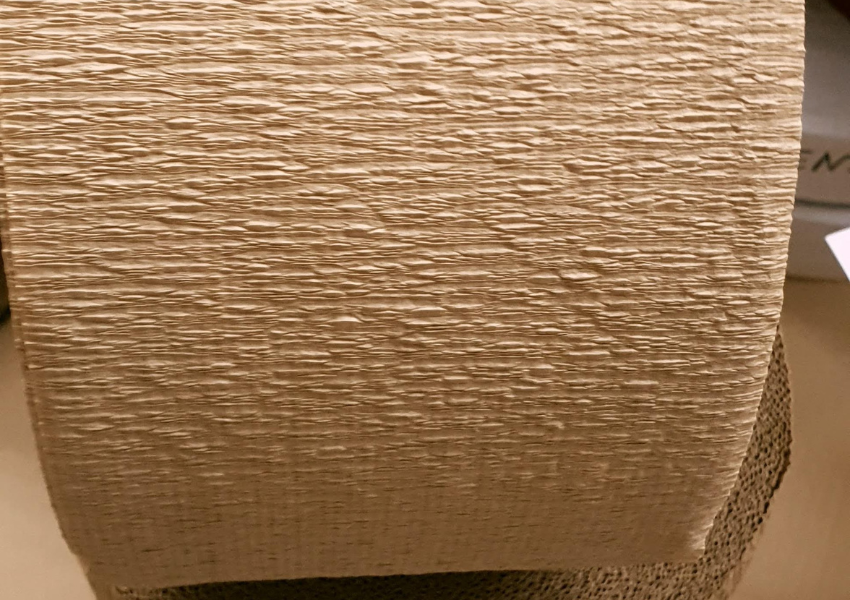

Crepe Paper as a Technical Packaging Material

Crepe paper is characterized by its crinkled texture, achieved through a creping process that gives it flexibility, tear resistance, and cushioning capacity. These properties set it apart from other conventional packaging materials, offering a unique combination of technical performance and sustainability.

At Arrosi, this type of paper is manufactured with high-quality virgin fibers, with controlled grammage, elongation, and absorption levels tailored to specific applications. Thanks to this precision, crepe paper can be used both for wrapping and protecting delicate parts and for stitching or sealing industrial sacks.

Technical Comparison: Crepe Paper vs. Other Packaging Materials

Choosing the right packaging material depends on factors such as required strength, moisture exposure, product type, or cushioning needs. Below is a summary of the key differences between crepe paper and some of the most commonly used packaging materials.

1. Crepe Paper vs. Plastic Packaging

Plastic has historically been the most widespread industrial packaging material due to its low cost and insulating properties. However, it has a high environmental impact and is complex to recycle.

Crepe paper offers significant advantages:

- Biodegradable and recyclable, it reduces the environmental footprint of logistics processes.

- High flexibility without the need for additives.

- Strong sustainability image, aligned with current market standards.

While plastics require chemical treatments to alter their properties, crepe paper naturally acquires its mechanical features through the creping process.

2. Crepe Paper vs. Corrugated Cardboard

Cardboard is a rigid and resistant packaging material, ideal for external box structures or containers. However, its stiffness makes it less suitable for wrapping irregular items or flexible closures.

In comparison:

- Crepe paper offers greater adaptability to irregular surfaces.

- It is lighter, reducing overall packaging weight.

- Stretching can be controlled, allowing for a perfect fit without tearing.

These two materials can be complementary: cardboard for structure, and crepe paper as an internal liner or reinforcement.

3. Crepe Paper vs. Foams and Synthetic Materials

Polyethylene or polyurethane foams are used to protect fragile items. While they offer excellent cushioning, they have environmental drawbacks and high energy costs in production.

Crepe paper, on the other hand:

- Cushions impacts thanks to its elastic structure.

- Requires no petroleum-based components.

- Easily integrates into industrial recycling processes.

In many applications—such as packaging electrical components or metal parts—crepe paper successfully replaces foam, offering equivalent protection with a lower environmental impact.

Key Advantages of Crepe Paper as a Packaging Material

Beyond its technical properties, crepe paper stands out for its overall efficiency within the supply chain. Its most relevant advantages include:

- Versatility: suitable for wrapping, insulating, lining, or sealing products.

- Sustainability: 100% recyclable and biodegradable.

- Customization: available in various weights, colors, and elongation levels.

- Industrial compatibility: suitable for automation, cutting, and stitching processes.

- Logistics savings: its lightness and compressibility reduce transport and storage costs.

These features make it a valuable technical ally for both primary and secondary packaging, replacing less sustainable materials without compromising quality.

Applications of Crepe Paper Across Different Sectors

The use of crepe paper has spread across various industries, each with specific needs in terms of protection, presentation, and efficiency.

Industrial Packaging

Used as a protective and cushioning element for metal, mechanical, or electrical parts. Its elongation capacity prevents breakage and scratches.

Food Industry

Thanks to its food-grade quality and lamination options with paraffin or polyethylene, crepe paper is used to wrap bakery goods, confectionery, or cheeses, providing a hygienic and safe barrier.

Electrical and Electronics Industry

Functions as an insulating and dielectric separator in transformers, coils, and other equipment due to its thermal resistance and dimensional stability.

Agriculture and Agri-food

Used for stitching and sealing industrial sacks, as well as protecting fruits, plants, and bulk products during transport.

Crepe Paper as a Benchmark Among Sustainable Packaging Materials

Choosing the right packaging material is key to ensuring product protection while minimizing environmental impact. Compared to plastics, foams, or conventional cardboards, crepe paper offers a technical and ecological balance: strong, adaptable, and sustainable.

In an industrial context where efficiency and environmental responsibility are increasingly critical, crepe paper stands out as one of the most advanced solutions in the world of packaging materials.

Arrosi Solutions for Sustainable Packaging Materials

At Arrosi, our expertise in developing technical packaging papers allows us to offer solutions tailored to the needs of each sector. Our products—such as crepe paper, polyethylene-laminated kraft paper, paraffin paper, and tissue gauze—cover the full range of industrial applications, from electrical insulation to sack sealing and surface protection.

Each paper type is manufactured under strict quality and traceability controls, ensuring consistency in grammage, elongation, and mechanical resistance. Moreover, Arrosi’s commitment to sustainability is reflected in the use of certified raw materials and responsible processes that reduce environmental impact without compromising technical performance.

In this way, Arrosi positions itself as a comprehensive supplier of sustainable packaging materials, combining innovation, safety, and environmental respect—offering industrial companies a reliable partner to move toward a circular economy based on paper.