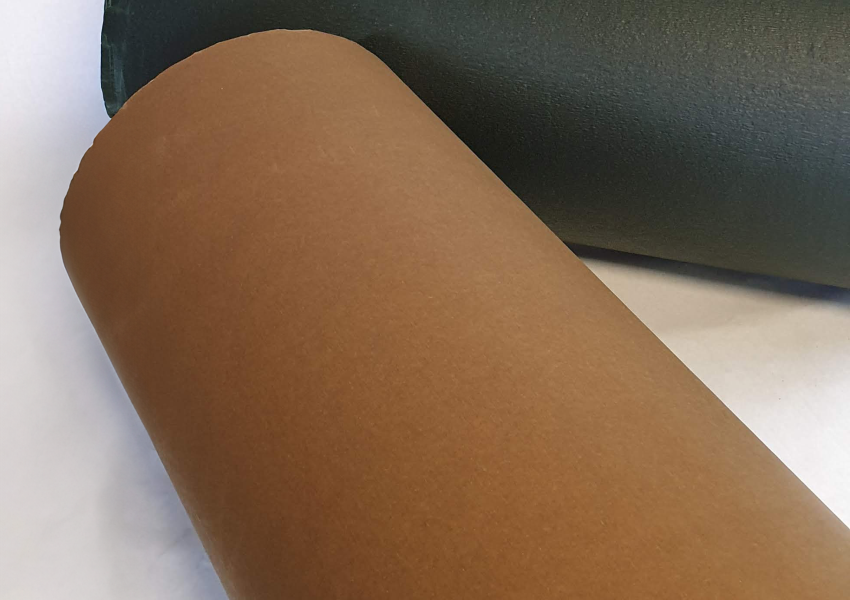

What is waxed paper?

Waxed paper is produced by impregnating paper with paraffin, a petroleum-derived substance which provides hydrophobic and protective properties. When this technique is applied to crepe paper, the result is a material that combines the elasticity and strength of crepe with the protective capabilities of paraffin.

At Arrosi, we take this combination to the next level, offering paraffined crepe paper specifically designed to protect industrial products and packaging under demanding conditions.

Key properties of waxed paper (and paraffined crepe paper):

- Moisture resistance:

Paraffin creates a waterproof barrier, ideal for protecting products in humid environments. - Elasticity and adaptability:

For paraffined crepe paper, the crepe structure adds extra flexibility, enabling to wrap complex-shaped objects without compromising protection. - Barrier against grease and oils:

Perfect for greasy products or industrial parts that need to remain contamination-free. - Enhanced durability:

The paraffining process increases the paper’s strength, making it suitable for repeated or prolonged use. - Recyclability:

When biodegradable or natural paraffins are used, these papers can be recycled, contributing to a more sustainable industry.

Uses of waxed paper at Arrosi

- Industrial packaging

Our paraffined crepe paper is ideal for wrapping mechanical parts, protecting metal components from corrosion, and ensuring that products reach their destination intact. - Food and pharmaceutical industries

While conventional waxed paper is widely used in these sectors, Arrosi’s paraffined crepe paper offers additional advantages in specific applications that require a more flexible and durable material. - Protection during transportation and storage

Paraffined crepe paper provides an effective solution for protecting delicate or valuable objects during transport, as its texture prevents slipping and damage. - Specialized applications

Paraffined crepe paper is also used in construction projects as a vapor barrier and in sectors requiring packaging with both protective and adaptable properties.

Advantages of paraffined crepe paper

- Superior flexibility: Thanks to its structure, paraffined crepe paper can adapt to irregular shapes without losing its protective properties.

- Greater strength: Compared with traditional waxed paper, paraffined crepe paper provides a more robust solution for industrial applications.

- Efficient material use: Its stretchability allows more surface coverage with less material.

Arrosi’s commitment to quality and sustainability

At Arrosi, we are not just dedicated to manufacturing crepe paper but also innovating by applying processes such as paraffining. This enables us to offer materials tailored to the specific needs of our clients, always with a focus on sustainability.

We work with responsible raw materials and optimized processes to minimize environmental impact. Moreover, we advise our clients to choose solutions that combine functionality with environmental respect.

Conclusion

Waxed paper, and more specifically paraffined crepe paper, is a key solution in many modern industries. Its unique properties, such as moisture resistance and adaptability, make it an indispensable material in industrial and food applications.

At Arrosi, we specialize in producing high-quality paraffined crepe paper designed to meet the most demanding needs. If you’re looking for innovative solutions for your industrial projects, don’t hesitate to contact us. We’re here to help you find the perfect product for your needs.