Why Bookbinding Materials Are Key to Book Quality

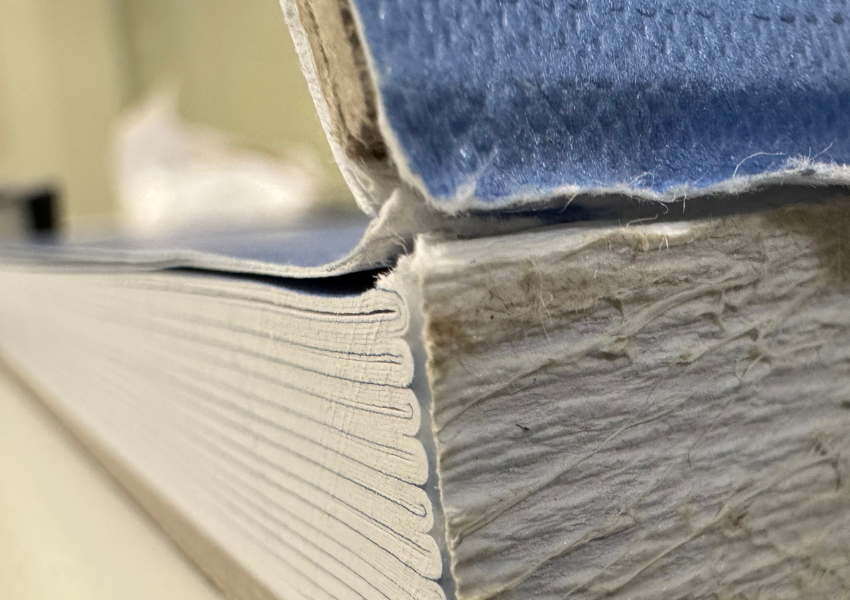

The bookbinding materials used for the spine, covers, or interior finishing have a direct impact on the book’s structural integrity, ease of opening, and lifespan.

From spine reinforcement to hardcover rigidity, each technical component ensures that the book remains in excellent condition even after frequent use.

Arrosi’s technical papers, designed for industrial and publishing applications, stand out for their dimensional stability, controlled grammage, balanced absorption, and calibrated elongation—essential factors for safe, automated bookbinding materials processes.

Crepe Paper: Controlled Elasticity for Spine Reinforcement

Among the most versatile and widely used bookbinding materials, crepe paper stands out in the manufacturing of books, planners, and notebooks. Thanks to its creped structure, it provides controlled elongation between 5% and 60% (depending on the needs of each project), allowing the paper to absorb stress and movement caused by gluing, sewing, or repeated openings.

At Arrosi, we manufacture crepe paper using virgin or recycled fibres, making it possible to adapt to the technical and environmental requirements of each editorial project:

- Virgin fiber offers higher mechanical strength for the same grammage.

- Recycled fiber enhances the sustainability image and environmental communication of the publishing house.

Common Uses of Crepe Paper in Bookbinding

Crepe paper is one of the most flexible bookbinding materials due to its elasticity and strength. It is commonly used in:

- Spine reinforcement of book blocks, especially in hardcover bindings.

- Sewn paperback bindings, where elasticity supports easy opening.

- Perfect bound books (milled), especially when used with EVA or PUR adhesives.

If you´d like to learn more about choosing the right grammage, check out our dedicated guide on how to select crepe paper grammage for bookbinding.

Spine Board: Rigidity and Structural Stability

The spine board is a key structural element in hardcover bookbinding materials. It provides rigidity, stability, and a uniform curve to ensure that the book opens and closes properly without deforming.

At Arrosi, we offer spine boards in various thicknesses and grammages adapted to the type of book, format, and binding process.

Key Advantages:

- Uniform curvature that facilitates the cover assembly.

- Clean folding, even on high-speed automatic lines.

- Dimensional stability that prevents warping due to heavy use or long-term storage.

Types of Binding and Recommended Arrosi Bookbinding Materials

Each editorial binding technique requires bookbinding materials with specific properties. Arrosi’s solutions are tailored to different systems:

Hardcover Binding

- Crepe paper for spine reinforcement.

- Headband for top and bottom finishing.

- Spine board to provide structural rigidity.

Sewn Paperback Binding

- Medium-elongation crepe paper to support book opening.

- Technical reinforcements adapted to post-gluing processes.

Perfect Binding

- Low-elongation crepe paper (5–15%)

- Thin reinforcement papers to improve adhesion and durability

These combinations ensure accurate, flexible, and durable binding, suitable for both artisanal and industrial production lines.

Sustainability in Bookbinding Materials

Publishers are increasingly seeking bookbinding materials that combine technical performance with sustainability.

Arrosi’s products are manufactured under principles of:

- Energy efficiency

- Resource optimisation

- FSC®-certified responsibly sourced fibres

- Recyclability and biodegradability

This approach helps reduce the environmental footprint of each book without compromising quality.

Technical Control: Grammage, Elongation, and Absorption

One of Arrosi’s key strengths lies in the technical control of crepe paper, tailored to the requirements of each binding:

- Grammages from 30 to 110 g/m²

- Calibrated elongation between 5% and 60%

- Controlled absorption and porosity for stable adhesion

This level of precision ensures consistent results and reduces adjustments on the production line.

Innovation and Collaboration with the Publishing Sector

At Arrosi, we work closely with publishers, printers, and machine manufacturers to adapt our bookbinding materials to the speed, adhesives, and configurations of each process.

This collaboration enables the development of custom solutions that maximise efficiency, minimise waste, and ensure stability across editions.

Frequently Asked Questions About Arrosi Bookbinding Materials

What types of bookbinding materials does Arrosi produce?

Arrosi produces crepe paper, endpapers, and spine boards tailored to the publishing industry.

What is the elongation range of crepe paper?

Between 5% and 60%, depending on grammage and final use.

Are Arrosi materials sustainable?

Yes. All products can be made with FSC® certification and are recyclable and biodegradable.

Does crepe paper improve book opening?

Yes. Its elasticity allows the spine to flex smoothly, especially in sewn softcovers and hardcover bindings.

Arrosi: Innovation and Precision in Bookbinding Materials

With decades of experience, Arrosi is a strategic partner for publishers seeking technical performance, reliability, and sustainability.

Our bookbinding materials crepe paper, endpapers, and spine boards—guarantee stable, precise results suited to today’s industrial processes.

Discover all our solutions at: https://arrosi.com/en